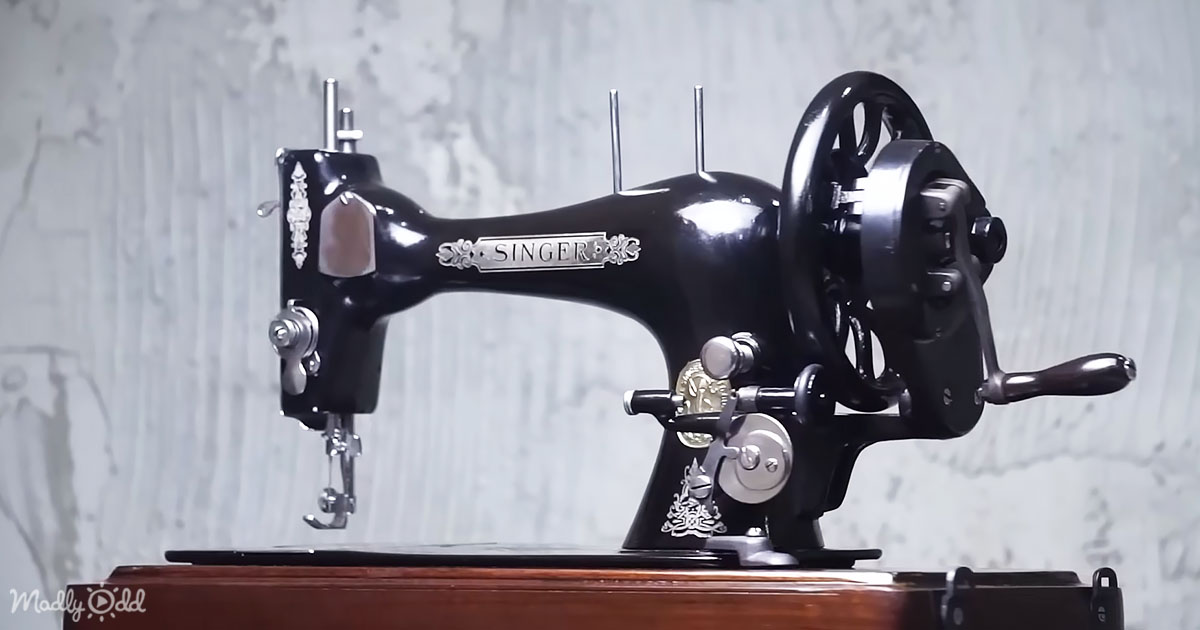

A remarkable video clip recently emerged, showcasing the meticulous revival of an 1894 SINGER sewing machine. This forgotten gem, tucked away in an abandoned henhouse, was a silent witness to a bygone era. Rust had crept in, and wear and tear had taken their toll. But in the hands of a master restorer, the journey of rediscovery begins.

He instantly captivates the viewers as he delicately brushes the rusted sewing machine. While doing so, he reveals the intricate details hidden beneath layers of neglect. With each stroke, the machine’s spirit comes alive as if echoing the rich tapestry of stories it holds.

Piece by piece, the restorer carefully disassembles the machine, treating each component with utmost respect. Rust remover spray is gently applied, coaxing stubborn residue away, while specialized tools aid in removing intricate screws. It’s a delicate balance of patience and determination, ensuring the preservation of this mechanical marvel.

With the parts separated, the restoration process delves deeper. The wooden components, weathered and worn, receive special attention. State-of-the-art sanding tools delicately caress the surfaces, revealing the natural beauty of the wood. After delicately disassembling the machine, the restorer begins the painstaking task of putting it back together.

Using glue to ensure each part returns to its original position, he expertly fills any holes with glue and the wood dust. Next, a polish glaze is applied to the wooden surfaces, bringing out the natural luster. Next, once caked in dirt, the iron components undergo a thorough cleaning process, meticulously removing every speck. Sandblasting then works its magic, eradicating the rust and transforming the once-decayed parts giving it an almost new look.

The talented restorer cleans each screw and component using a bench grinder to achieve a polished appearance. Using sandpaper further enhances the shine, leaving the parts looking as good as new. Next, his attention turns to the metal base, where a polyester putty is carefully applied, creating a smooth and flawless surface.

The screws are thoroughly cleaned with oil before being plated with nickel, adding a fresh touch to their appearance. A final coating of white lining on the metal body ensures that the black paint sits perfectly, completing the visual transformation.

But the restorer doesn’t stop there. With a touch of artistry, decorative motifs are intricately applied to the metal base using a laser process. This exquisite detail work completely revolutionizes the look of the sewing machine. Then, piece by piece, the restorer carefully places all the components back in their original positions, ensuring every detail is perfectly aligned.

Before showcasing the restored machine, the restorer takes the time to properly oil all the parts. He then connects the thread and guides it through the needle, ready to demonstrate the machine’s brilliance. As the machine springs to life, it effortlessly glides through the fabric, creating perfect stitches with each pass. The restorer even crafts a pillow cover with finesse and precision to showcase the machine’s capabilities.

After 2 months of painstaking work, the restoration finally completes. What once seemed like an insurmountable task has been conquered with unwavering determination and skill. The transformation is remarkable, leaving viewers in awe of the restorer’s expertise. Many viewers commented that tackling a project of this magnitude requires the touch of a specialist equipped with specialized tools and knowledge of materials.